Lithium-ion batteries are a kind of green and clean energy, and are the main power supply devices in the current consumer electronics, pure electric vehicles, hybrid electric vehicles, data centers, energy storage and other market fields. High energy density, long cycle life, and high rate charge and discharge performance will become the main direction of the future market development of lithium-ion batteries.

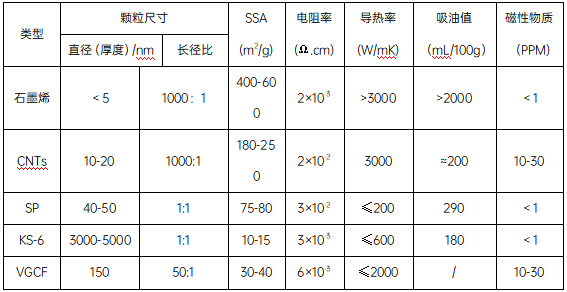

The conductivity of lithium-ion battery cathode materials is low, and in order to improve the electron transport ability, a small amount of conductive agent needs to be added to the material to build a dense conductive network. Conductive agents have a very important impact on improving the performance of the battery, such as cycling, capacity play, and rate charging and discharging. The new conductive agent graphene is a two-dimensional planar structure molecule composed of carbon atoms in the form of sp2 hybridization, and its extended honeycomb network structure is the basic building unit of graphitized materials, with a powder resistivity of only 2×10-3Ω.cm and a thermal conductivity of 3000-5000W/mK, which has great performance advantages in the field of electrical and thermal conductivity.

The thickness of the sheet of graphene is below 3nm, which has the characteristics of thinness and flexibility, and the contact between the graphene and the cathode particles is a flexible surface, which will greatly increase the electron transport channel of the cathode material, thereby minimizing the amount of conductive agent and ultimately improving the capacity of lithium-ion batteries. On the other hand, it can buffer the volume expansion and contraction of the active material during the charging and discharging process, inhibit the rebound effect of the pole piece, and ensure the good cycle of the battery. Compared with the traditional lithium-ion battery conductive agent, it has the characteristics of ultra-low permeation threshold, non-magnetic substance content, strong liquid absorption and retention capacity, and high compaction density, and the amount added to the battery is only 20-30% of that of the traditional conductive agent. Xinsijie Industry Research Center predicts that China's graphene conductive agent industry will continue to maintain a strong growth trend in the next few years. It is estimated that in 2022, the market size of China's graphene conductive agent will grow to 21.573 billion yuan.

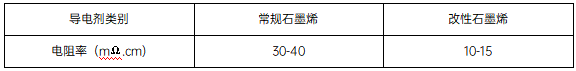

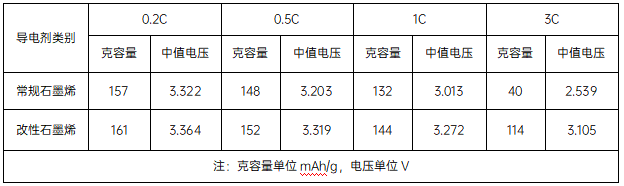

Table 1 Performance parameters of conductive agents for lithium-ion batteries

Graphene is a nanoscale material, in addition to the characteristics of large specific surface area, it also has a strong van der Waals force between layers, so it is easy to agglomerate between the sheets, and it is difficult to disperse in aqueous or oily systems. The unevenly dispersed graphene conductive paste may lead to the sedimentation of the slurry and the problem of lamellar relapse after long-term storage, which will eventually affect the real performance of graphene. How to ensure the quality of graphene and achieve graphene conductive paste with good dispersion stability in water or organic solvent system has always been an urgent problem to be solved in the industry.

In view of the difficulty of graphene dispersion, Morion Nanotech has built an elite team in the field of carbon materials through the process development model of "learning-research-production-application" to solve various practical problems faced by graphene industrialization. From theory to practice, we have consolidated every technology development link, accumulated a lot of original data and practical experience in the development of graphene materials, and played a strong role in promoting the modification development of graphene products to product application.

In order to develop high-quality graphene conductive paste, in addition to the most advanced dispersion equipment in the industry (such as high-speed shear mixer, sand mill, high-pressure homogenizer, etc.), Morion Nanotech focuses on two chemical dispersion processes: non-covalent and covalent functionalization modification of graphene. In terms of non-covalent functionalization modification, we use benzene ring-rich polymer materials as dispersants, and improve the dispersion effect of graphene through the principle of π-π interaction between the benzene ring of the dispersant and the six-membered ring of graphene. The outer three electrons of a single C atom in the six-membered ring of graphene are hybridized by sp2 to form a strong σ bond, and the angle between the three adjacent bonds is 120°, and the fourth is a common electron, forming a weak π bond. The C-C bond of graphene is about 0.142nm long, there are three σ bonds in each crystal lattice, and the p orbitals of all carbon atoms are perpendicular to the sp2 hybrid plane, and form a delocalized π bond side by side, which runs through the entire graphene, and because the benzene ring can form a π-π bond interaction with graphene, its dispersion can be improved through the π-π interaction in the functionalization of non-covalent bonds. In terms of covalent bond functionalization, the covalent bond modification is achieved by combining the abundant carboxyl, hydroxyl and epoxy groups on the surface of graphene oxide with foreign functional groups to improve the dispersion of graphene.

The functionalized graphene conductive paste is further improved compared with the conventional graphene conductive paste in terms of slurry stability, adhesion, resistivity and electrical properties.

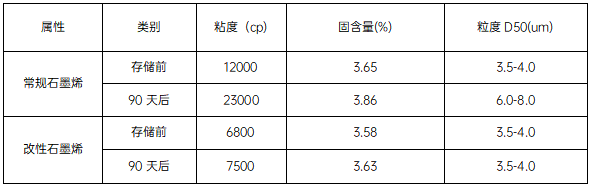

Table 2 Graphene conductive paste was stored for 90 days

After 90 days of natural storage, the solid content, viscosity and particle size of the modified graphene slurry have basically no obvious change, and the stability is better than that of conventional graphene.

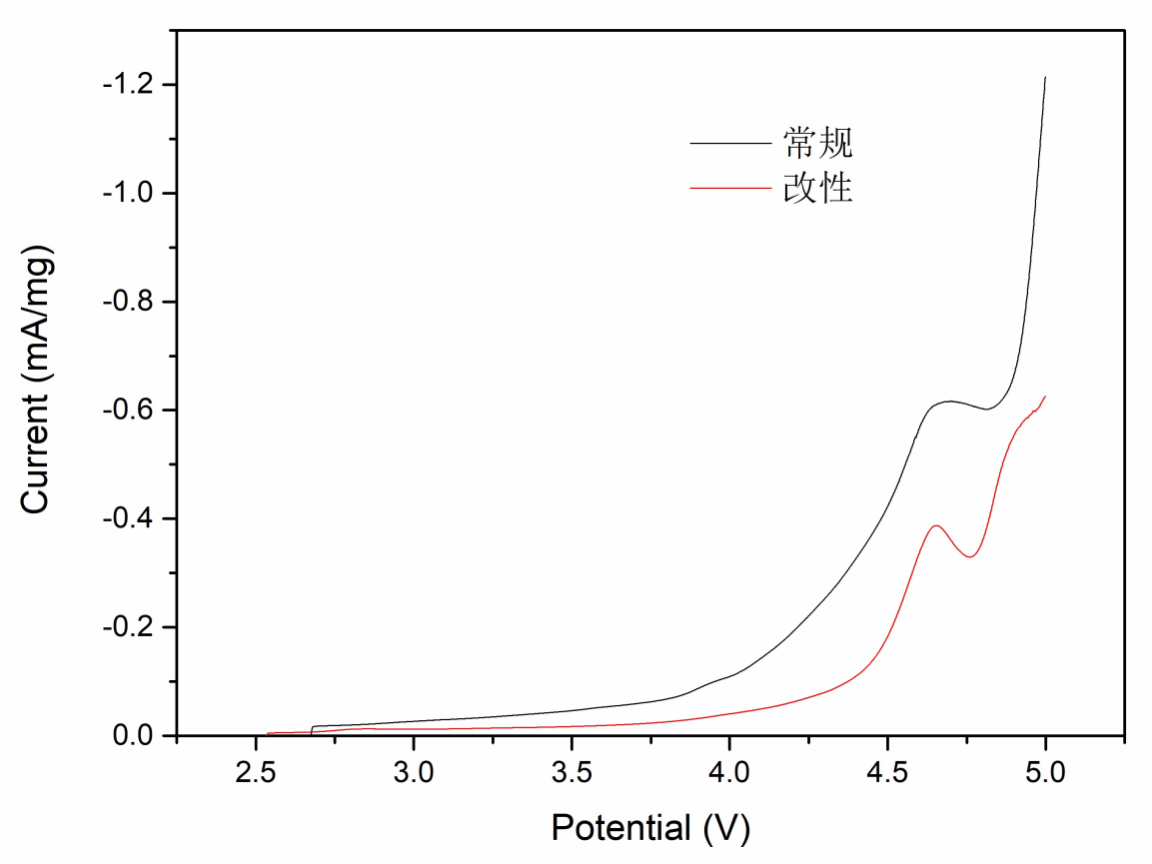

Fig.1. Linear scanning voltammetry curve (LSV) of graphene conductive paste

In terms of the high-voltage stability of graphene conductive paste, the electrochemical method was used to evaluate it. According to the ratio of conductive paste:binder = 80:20, the electrode piece was mixed into a pole piece, and the CR2032 button battery was assembled together with lithium sheet, electrolyte and separator, and its LSV performance was tested, and the voltage scanning interval was -5V with an open-circuit voltage of -5V and a scanning rate of 0.5mV/s. The results show that the oxidation current of the modified graphene paste is lower than that of the conventional graphene conductive paste in the voltage range of 3-5V, indicating that it has good compatibility with the electrolyte, remains stable at high voltage, has no side reactions, and has no safety risks.

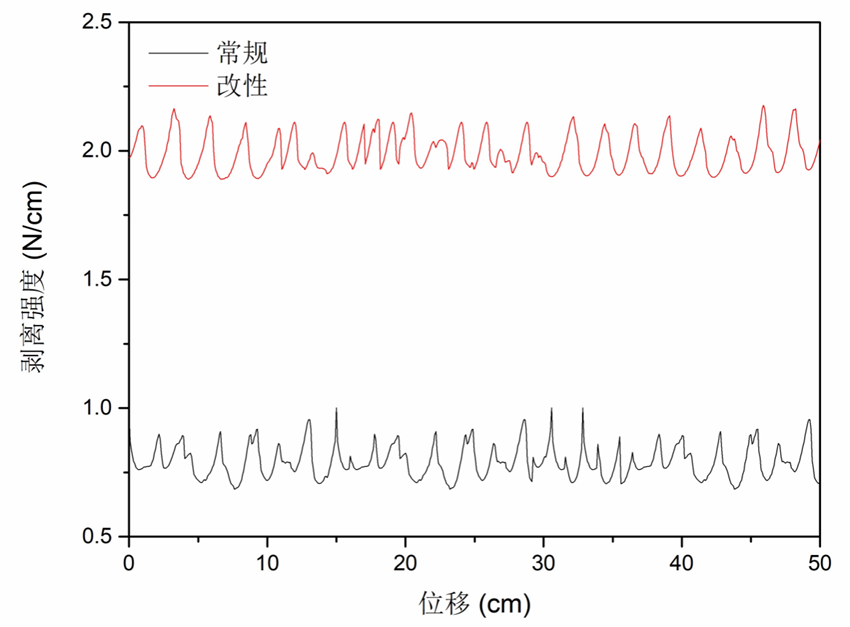

Fig.2. Adhesion of graphene conductive paste

The dispersant content of graphene conductive paste is basically 0.5%-1%. Under the same addition amount, the peeling force value of the modified graphene conductive paste on the aluminum foil of the lithium-ion battery matrix will be greatly improved, and the peeling strength will reach more than 120N/m, and the content of the original binder will be significantly reduced when used with the cathode. At the same time, the high adhesion of the pole piece will further improve the reliability and cycle life of the battery.

Table 3 Powder resistivity of graphene conductive paste

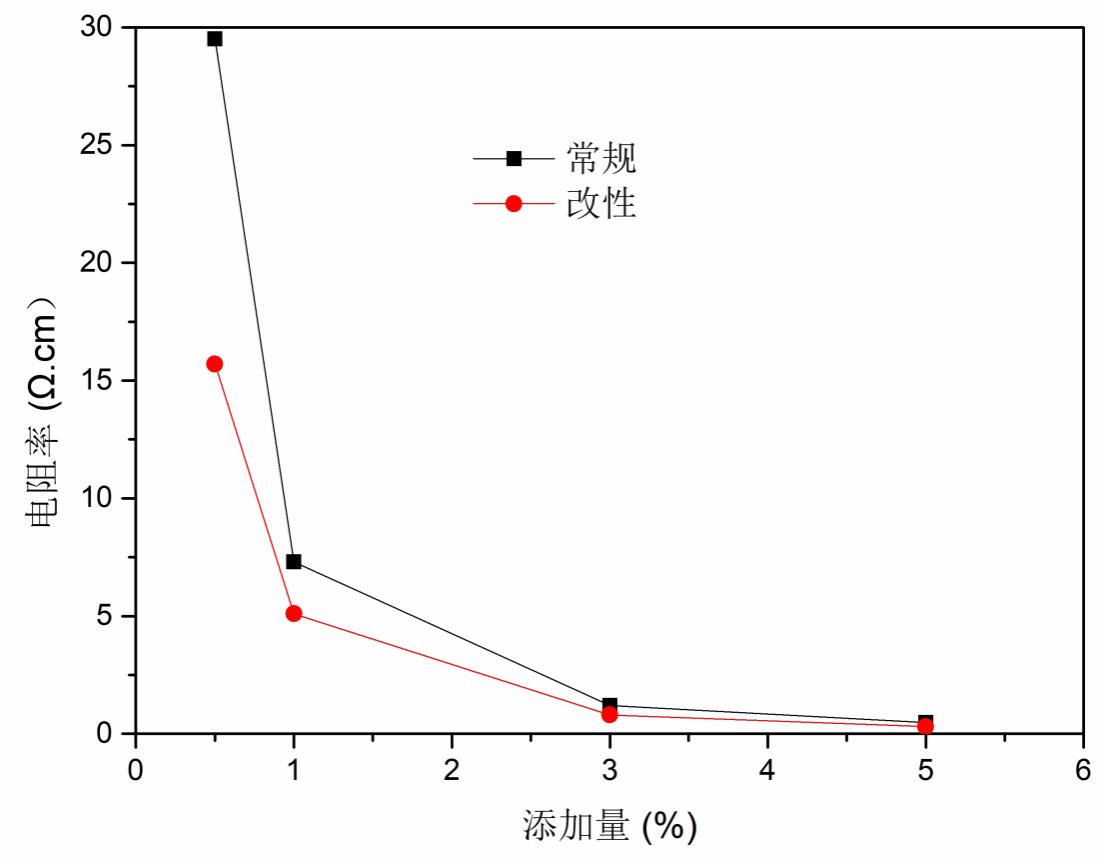

图3 石墨烯导电浆料在LFP的渗透阈值

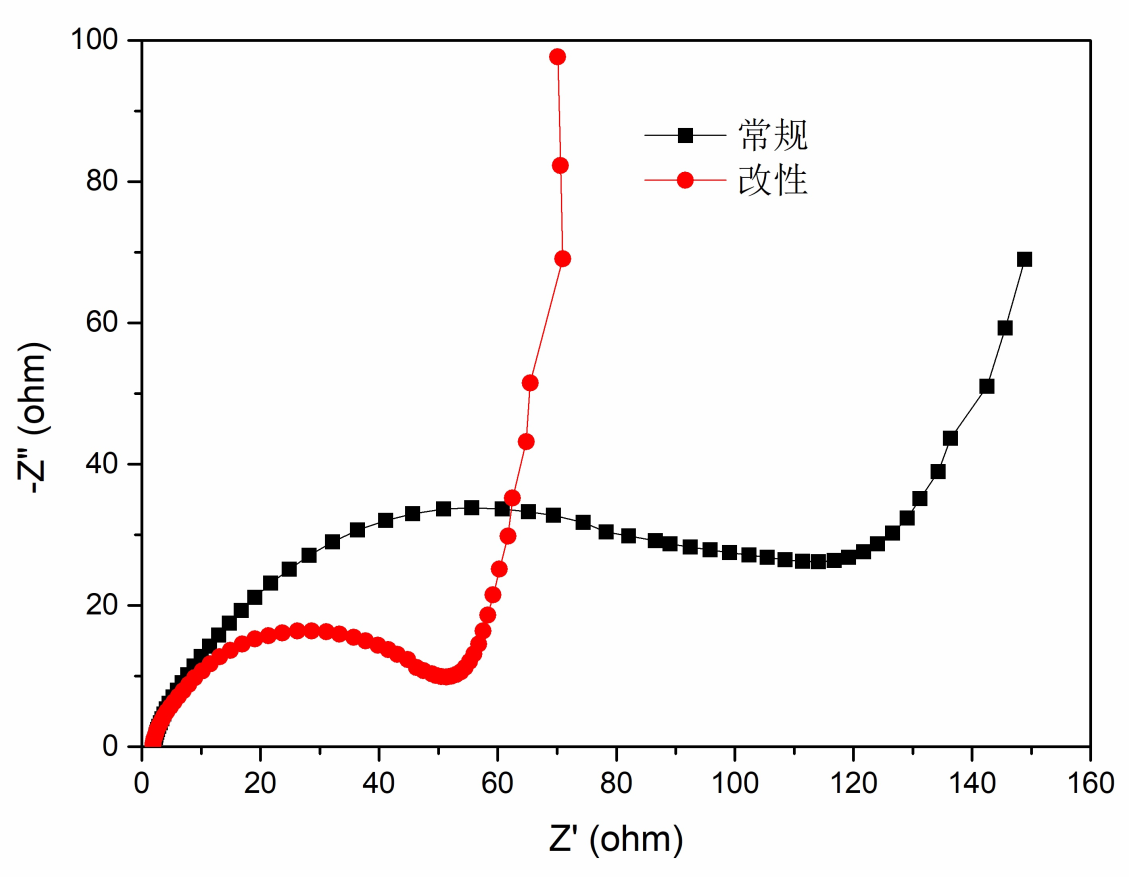

Fig.4. AC impedance spectrum of graphene conductive paste in LFP

The electronic conductivity of graphene is excellent, and the resistivity of conventional graphene powder has reached 30-40mΩ.cm, which is incomparable with other conductive agents, and the resistivity of graphene after modification has reached 10-15mΩ.cm, and the performance has been improved by more than 1 time. In terms of the permeation threshold of LFP cathode material, the modified graphene also has a low threshold window, and the resistivity of the electrode piece reaches less than 5Ω.cm at the addition amount of 1%. From the perspective of electrochemical impedance spectroscopy, the charge transfer impedance of modified graphene is reduced by 50%, and the steric resistance effect of graphene is also effectively solved, and the rate and fast charging performance will be exerted to the extreme. The highly uniformly dispersed modified graphene avoids the problem of graphene flake agglomeration, and each piece of graphene will play an excellent role, and finally achieve high conductivity and interoperability between materials.

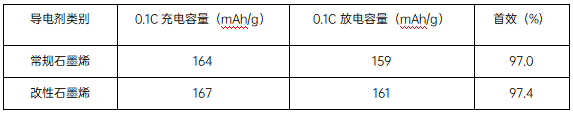

Table 4 Capacity and first effect of graphene conductive paste in LFP (button battery)

Table 5 Rate performance of graphene conductive paste in LFP (button battery)

The addition of graphene conductive paste in the LFP cathode material is 2.5%, and its 0.1C is charged and discharged for the first time, and the gram capacity is 160mAh/g, and the first effect reaches 97%, showing excellent performance. In addition, in terms of rate performance, the modified graphene has better performance than conventional graphene in terms of 1C and 3C rate discharge performance, with the 1C capacity increased by 9% and the overall energy density increased by 18%. The excellent performance of rate performance is due to the fact that the modified graphene is more conducive to uniform dispersion, which not only improves the electronic conductivity but also avoids the secondary agglomeration of graphene, and makes it easier to prepare high-quality cathode slurry, which solves the ion steric hindrance effect caused by agglomerated graphene to a certain extent. In addition, according to the characteristics of LFP cathode nanomaterials, the diameter and pore structure of the modified graphene sheet were accurately adjusted in both directions, and finally the rate performance of the lithium-ion battery was significantly improved.

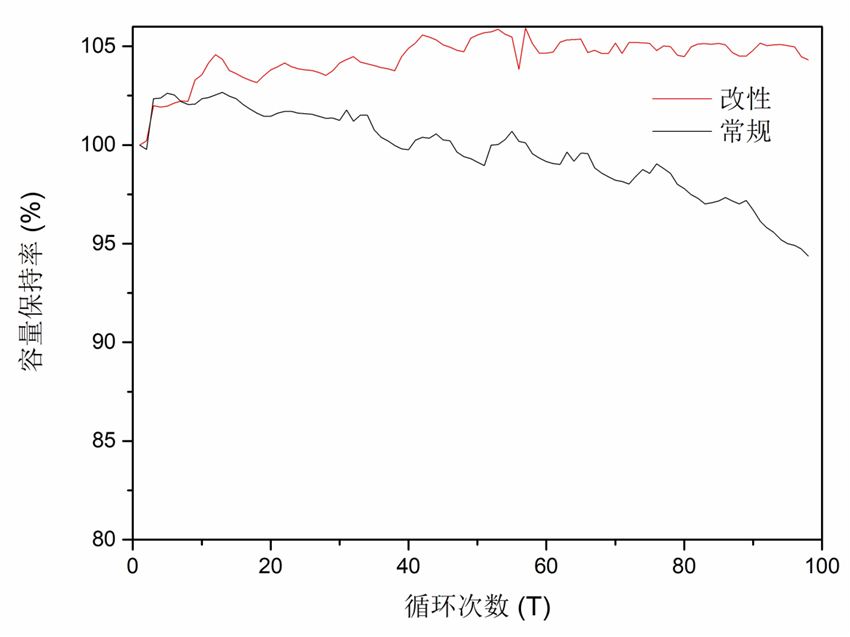

Figure 5: Cycling properties of graphene conductive pastes in LFP

The LFP button battery prepared with modified graphene conductive paste had nearly 100 cycles in 1C, and the capacity was almost attenuated, showing an excellent level of cycling performance. The development of lithium-ion battery technology with a longer life will play an irreplaceable role.

Through the modification of conventional graphene, Morion Nanotech obtains a highly dispersed and uniform graphene conductive paste, which solves the problem of secondary agglomeration or lamellar refolding of the slurry. The storage stability, resistivity, ion impedance, and electrical properties of the slurry have been significantly improved compared with conventional graphene products, which plays a vital role in the further improvement of the high energy density, long cycle life, and high-rate charge-discharge performance of lithium-ion batteries, and will better serve the development of high-performance lithium-ion batteries.

*The copyright of the content belongs to Morion Nanotechnology Co., Ltd. The pictures and articles shall not be reproduced without permission, nor shall the published content be distorted or tampered with. If reproduced, the source of the pictures and text shall be noted: Morion Nanotechnology Co., Ltd.

Guangdong Public Security Registration No.44190002005690

Guangdong Public Security Registration No.44190002005690