Recently, Morion Nanotech collaborated closely with an academic team from Kunming University of Science and Technology to conduct in-depth research on high thermal conductivity graphene-paraffin composite materials, achieving significant results. This research has been published in the prestigious SCI journal 'Applied Thermal Engineering' under the title 'Highly thermal conductive Graphene/Paraffin composite for efficient thermal management of electronics'.

In today's society, microelectronic devices such as smartphones, laptops, and chip-embedded systems have become essential components of daily life and industrial production. With the rapid development of information and communication technology and the increasing trend towards miniaturization and integration of electronic products, the effective heat dissipation of electronic devices has become a critical factor affecting their lifespan and operational efficiency. Even a slight temperature increase can cause a 'thermal collapse' of the device, severely impacting its reliability and lifespan. Therefore, in the research and deployment of microelectronic devices and systems, it is crucial and urgent to seek effective and practical thermal management materials and methods to ensure the performance and reliability of the devices.

Phase change materials (PCMs) are a promising thermal management solution. PCMs can absorb large amounts of heat during phase transition and release stored energy when needed. However, pure phase change materials like paraffin have low thermal conductivity (about 0.21 W/m·K), which increases the response time for temperature changes and may lead to significant leakage during phase transition, limiting their direct application in electronic devices.

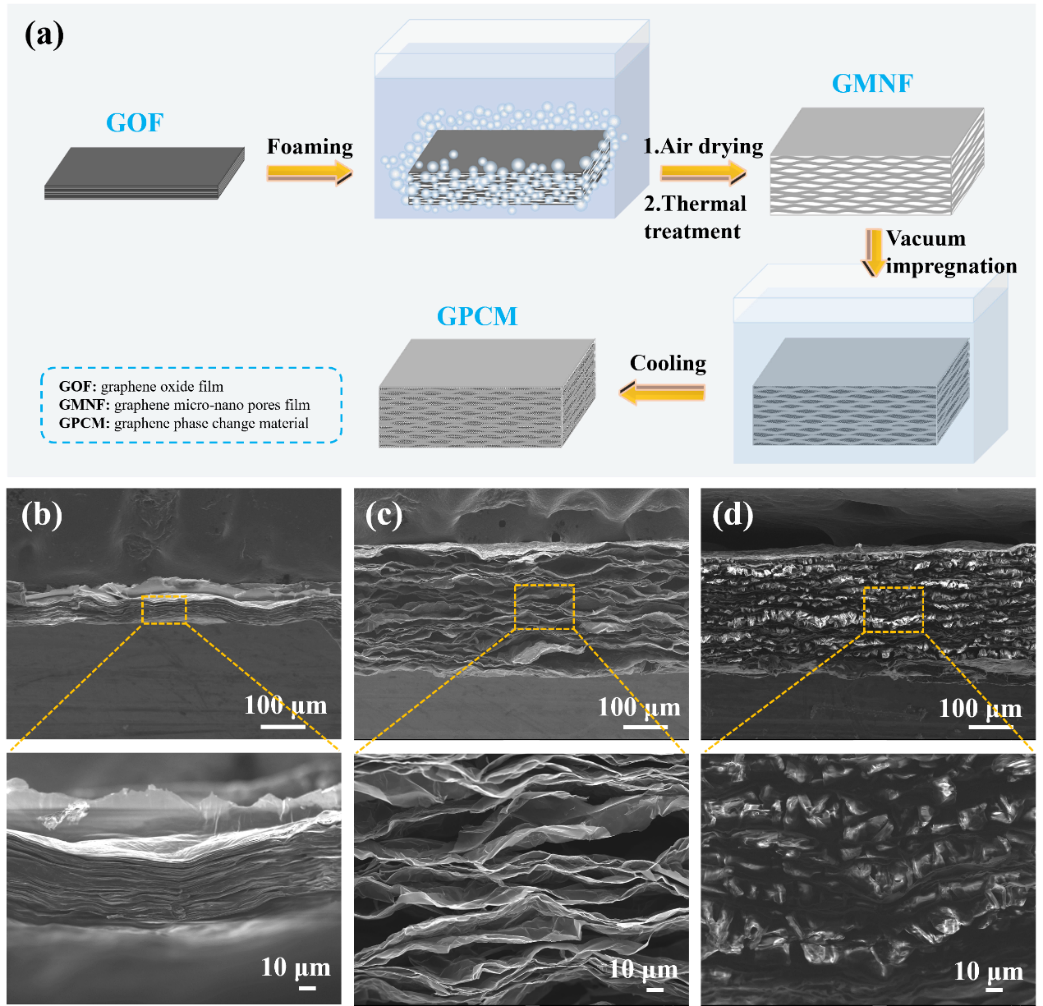

To overcome this challenge, the Morion Nanotech research team utilized graphene's large specific surface area, excellent thermal conductivity, and good mechanical properties, incorporating it into composite phase change materials to stabilize shape and enhance rapid heat transfer. Using chemical foaming methods, the team successfully structured a 120μm thick graphene oxide coating film (GOF) into a three-dimensional architecture with micrometer and nanometer-sized cavities. After drying and high-temperature thermal treatment, these unique cavity structures were retained, resulting in a graphene micro-nano porous film (GMNF) approximately 350μm thick. Further combining GMNF with paraffin, the cavities within the GMNF were filled with paraffin, yielding the desired graphene phase change thermal management sheet (GPCM).

Figure 1 (a) Schematic diagram of the preparation process principle for graphene phase change thermal management plates; (b-d) Microscopic morphology structure diagrams of graphene oxide coated film (GOF), graphene micro-nano pore film (GMNF), and graphene phase change thermal management plates (GPCM)

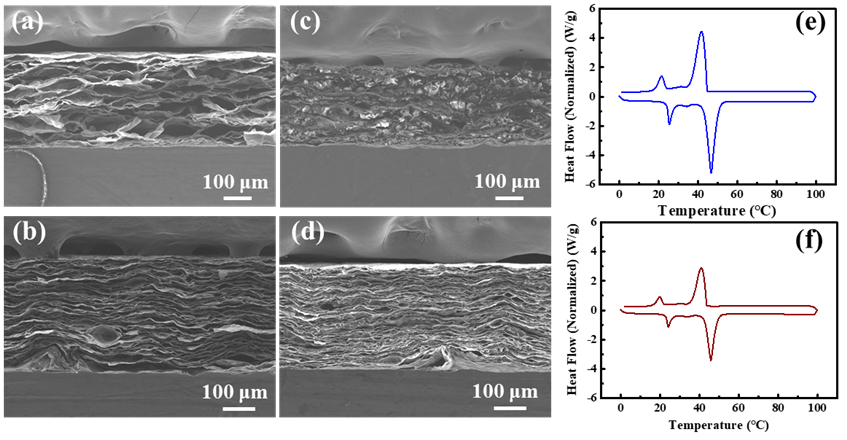

The research results show that when GMNF accounts for 20.6% of the total material mass, GPCM exhibits outstanding high thermal conductivity [thermal conductivity reaching 208.08 W/(m·K)] and heat absorption (156.97 J/g). Additionally, by regulating the thickness of GOF and the foaming agent, the three-dimensional structuring of graphene can be effectively controlled, thereby meeting the preparation requirements for GPCM with different performance needs.

Figure 2 shows two different structures and properties of GPCM obtained by adjusting the thickness of the GOF precursor film

As an efficient heat dissipation material, graphene phase change thermal spreader (GPCM) regulates temperature by altering the state of matter, providing stable and efficient cooling solutions for high-power devices such as smartphones, laptops, and communication base stations. When the device temperature rises, the phase change material quickly absorbs heat and undergoes phase transition, effectively lowering the peak temperature of the device for efficient cooling. When the device temperature drops, the phase change material rapidly returns to its solid state, achieving cyclic cooling and ensuring long-term stable operation of the device. This mechanism keeps the device temperature consistently within the ideal range, effectively extending the device's lifespan, improving stability, and addressing the critical issue of 'thermal collapse.' Currently, graphene phase change thermal spreaders have been applied in well-known terminal products from brands like ZTE and Xiaomi, receiving high praise and recognition from users.

Morion Nanotech's significant breakthrough in graphene phase change thermal management technology has brought an efficient and practical thermal management solution to current high-power, high-integration, high-energy consumption, and miniaturized electronic devices. Moving forward from great achievements and developing amidst the flow of challenges, Morion Nanotech will adhere to its original mission, continue to develop more high-quality graphene products, introduce even more efficient thermal management solutions, drive technological innovation and industrial upgrading, and inject new vitality into the continuous development of the graphene industry.

*The copyright of the content belongs to Morion Nanotechnology Co., Ltd. The pictures and articles shall not be reproduced without permission, nor shall the published content be distorted or tampered with. If reproduced, the source of the pictures and text shall be noted: Morion Nanotechnology Co., Ltd.

Guangdong Public Security Registration No.44190002005690

Guangdong Public Security Registration No.44190002005690