【1】Background Introduction

The rapid innovation in the electronics industry has driven microelectronics devices towards miniaturization and integration, leading to significant attention on heat spots and thermal failure of electronic devices. An efficient thermal management system is crucial for ensuring the stable and safe operation of high-power electronic equipment. Electronic packaging materials are part of integrated electronic products and typically use inexpensive, easy-to-process, corrosion-resistant polymer materials. However, most polymers have an intrinsic thermal conductivity that is very low (0.1-0.3 W/m·K), severely limiting their effective use in thermal management of electronic devices.

Therefore, developing high thermal conductivity polymer-based electronic packaging materials is a crucial part of electronic thermal management. Generally, an effective way to enhance the thermal conductivity of polymers is to fill them with high thermal conductivity fillers, such as graphene, boron nitride, and carbon nanotubes. Among these, graphene, with its extraordinarily high in-plane thermal conductivity (3500-5300 W/m·K) and excellent mechanical properties, has revolutionized the field of thermal materials. Over the past few decades, graphene has often been used as a dispersed filler to enhance the thermal conductivity of polymers. However, the significant interfacial thermal resistance between fillers and between fillers and the polymer severely limits the formation of effective phonon transport pathways within the polymer. Consequently, this requires a higher mass fraction of fillers to achieve effective thermal conductivity enhancement, which results in more interfaces within the polymer, further deteriorating its mechanical properties.

In recent years, pre-assembling interconnected three-dimensional (3D) graphene frameworks followed by polymer backfilling has proven to be an extremely effective method for manufacturing polymer composites with improved performance. The pre-formed graphene framework provides a complete and efficient pathway for phonons within the polymer, achieving high thermal conductivity at low graphene loadings while maximizing the mechanical properties of the polymer composites. However, chemical vapor deposition (CVD) is limited in preparing larger volumes of 3D graphene networks, and the process is complex and expensive. Additionally, the bidirectional freezing method requires sophisticated equipment, making industrial production challenging. Generally, enhancing high thermal conductivity at lower filler contents remains a key issue.

【2】Highlights of Achievements

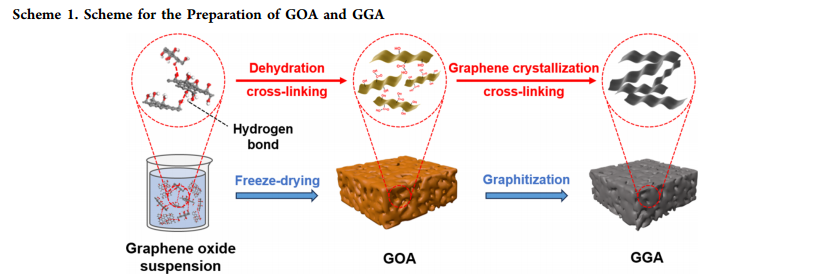

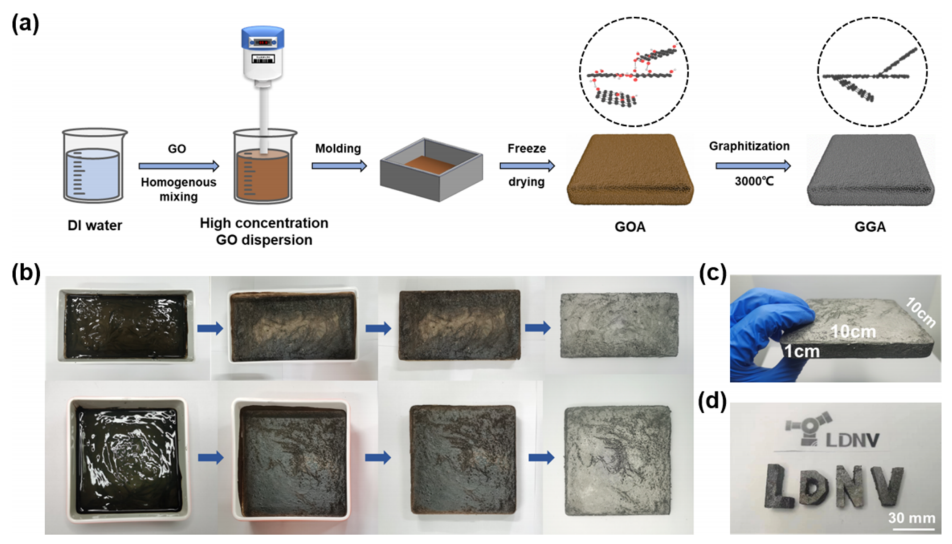

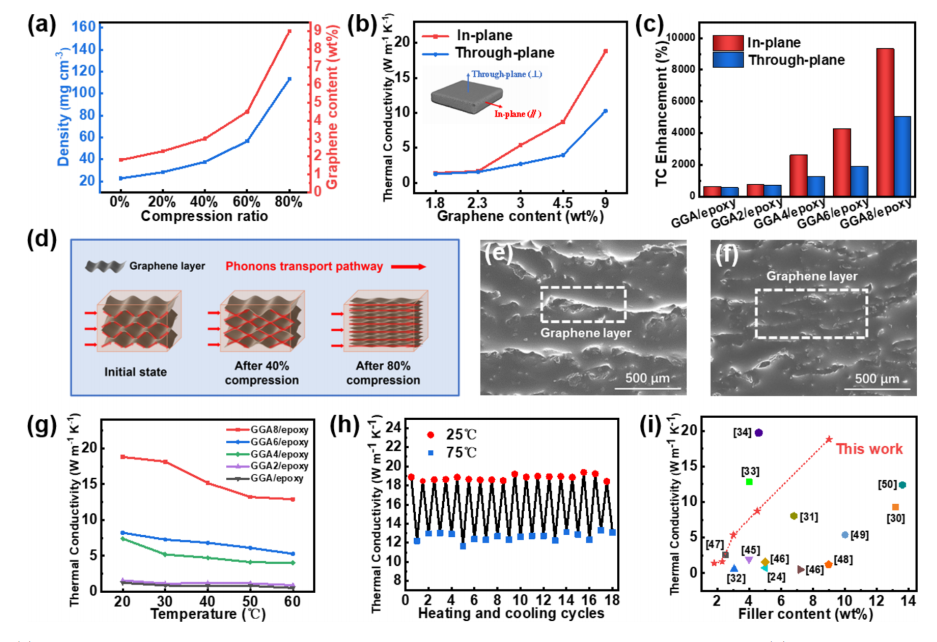

Recently, a team led by Cai Xiaoming and Cai Jinming from Kunming University of Science and Technology made significant progress in the synergistic regulation of thermal and mechanical properties of thermal conductive fillers. One effective method to enhance thermal conductivity with low filler content is to prepare interconnected graphene nanoplate frameworks in polymers. However, current methods for preparing graphene nanoplate frameworks are usually complex and have low cross-linking density. In this study, they fabricated high-quality graphene nanoplate frameworks with high cross-linking density. By utilizing the self-assembly properties of graphene oxide, they prepared three-dimensional cross-linked graphene oxide aerogels (GOA) using an ice-template method. After high-temperature treatment at 3000°C, they obtained graphite graphene aerogels (GGA) with high thermal conductivity and excellent mechanical properties. They compressed GGA to varying degrees and then infiltrated it with epoxy resin to produce a series of GGAx/epoxy composite samples. When the graphene content was only 9 wt%, the in-plane thermal conductivity of the epoxy composite reached 18.8 W/m·K, resulting in a thermal conductivity enhancement of 1034% per 1 wt% of graphene loading, which surpasses most traditional graphene network structures used in polymer phonon pathways.

This study presents a simple method for preparing graphene nanoplatelet frameworks with high cross-linking density, which offers insights into the future development of graphene nanomaterials for electronic packaging heat dissipation. The research findings were published in 'ACS Applied Nano Materials' under the title 'Thermally Conductive Epoxy Resin Composites Based on 3D Graphene Nanosheet Networks for Electronic Package Heat Dissipation'.

Plan 1: Compilation plan for GOA and GGA

【3】Illustrated Guide

Figure 1. (a) Schematic diagram of the manufacturing process for GOA and GGA. (b) The shape of the GGA sample can be customized according to the mold shape. (c) The macroscopic dimensions of the square GGA sample. (d) The GGA sample has excellent customizability.

Figure 2. (a) Schematic diagram of structural changes after GOA graphitization. (b, c) SEM images of GOA cross-sections. (d, e) SEM images of GGA cross-sections. (f) XRD spectra of GOA, CRGA, and GGA. (g) Raman spectra of GOA, CRGA, and GGA. (h) XPS spectra of GOA, CRGA, and GGA. (i) FTIR spectra of GOA, CRGA, and GGA.

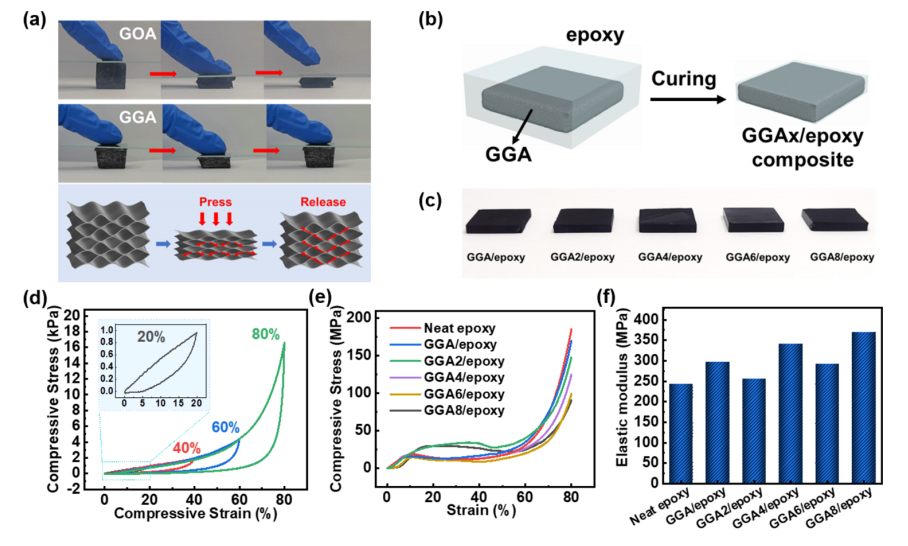

Figure 3. (a) Schematic diagram of the GOA and GGA compression rebound process and GGA force model simulation. (b) Schematic diagram of the GGA/epoxy composite material preparation process. (c) Samples after crop planting in the GGAx/epoxy series. (d) Stress-strain curves of GGA under 20%,40%,60%, and 80% compression strains. (e) Compressive strength and compression modulus of pure epoxy resin and GGAx/epoxy resin. (f).

Figure 4. (a) The relationship between GGA density and its content in composites as a function of GGA compression ratio. (b) In-plane thermal conductivity and through-plane thermal conductivity of GGAx/epoxy resin as a function of graphene content. (c) Enhanced thermal conductivity (TCE) of GGAx/epoxy resin. (d) Schematic diagram illustrating the enhancement of thermal conductivity in composites due to GGA compression. (e) SEM image of the cross-section of GGA/epoxy resin. (f) SEM image of the cross-section of GGA8/epoxy resin. (g) Thermal conductivity of GGAx/epoxy resin samples at different temperatures. (h) Thermal conductivity of GGA8/epoxy composite materials after multiple heating and cooling cycles. (i) Comparison of thermal conductivity with other three-dimensional graphene-based composites.

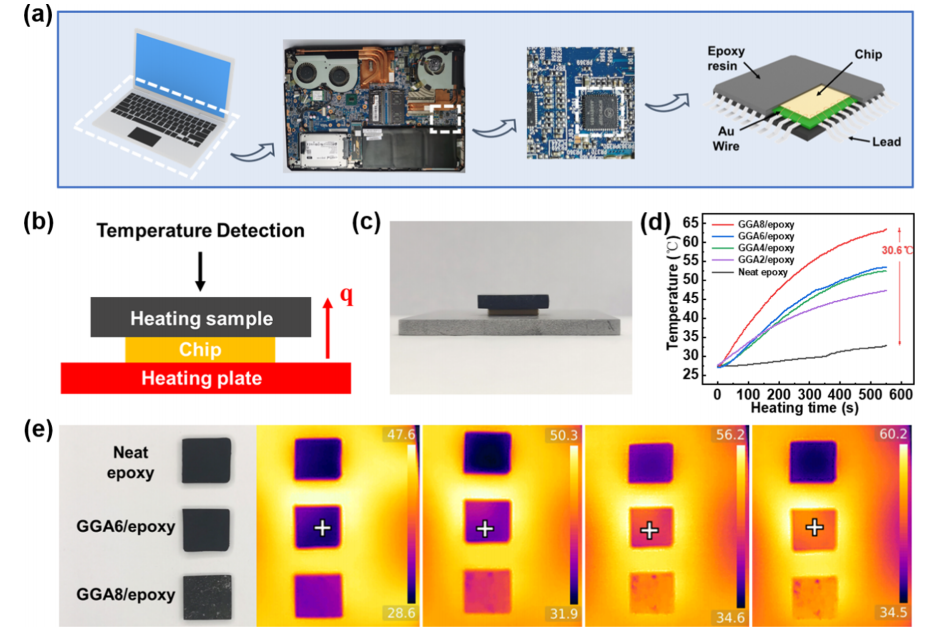

Figure 5. (a) Schematic diagram of epoxy resin used for computer chip packaging. (b) Configuration for testing the heat transfer capability of the packaging material and (c) its optical image. (d) Temperature rise curves of GGAx/epoxy resin samples and pure epoxy resin. (e) Comparison of infrared images after heating of pure epoxy resin, GGA6/epoxy resin, and GGA8/epoxy resin.

Source of information | Insight thermal management

The full text of the article | https://doi.org/10.1021/acsanm.4c01139

Guangdong Public Security Registration No.44190002005690

Guangdong Public Security Registration No.44190002005690