The "dual carbon" goal is a major strategic decision made by China based on the responsibility of promoting the construction of a community with a shared future for mankind and the inherent requirements of achieving sustainable development. The realization of this goal involves not only the optimization and adjustment of the energy structure, but also the improvement of energy efficiency and the reduction of the scale of fossil energy use, and the development and application of carbon reduction technologies such as energy conservation.

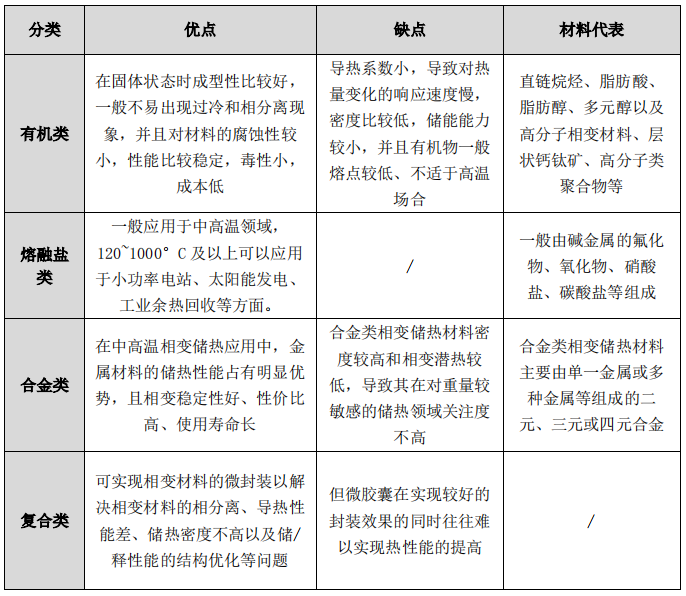

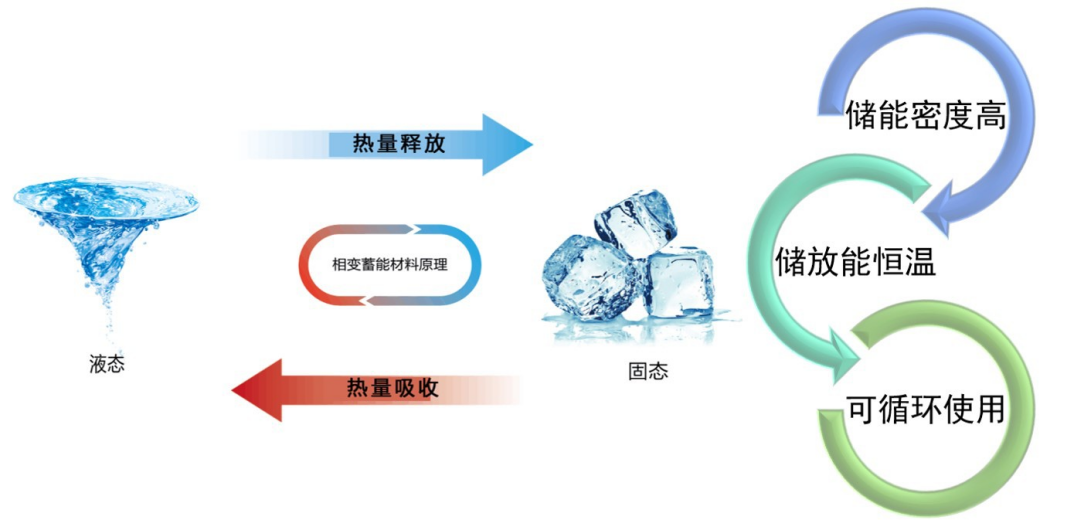

Phase Change Materials (PCMs) are extremely important development objects in the process of China's implementation of the "dual carbon" goal, and are expected to become the best green environmental protection carrier for energy conservation and environmental protection. Specifically, PCM refers to a class of energy storage materials that absorb or release a large amount of energy to regulate temperature during the phase transformation process. According to the type of phase change, it can be divided into solid-solid, solid-liquid, solid-gas and liquid-gas PCM. Based on the operability of practical applications, two types of research and applications, solid-solid and solid-liquid, are more common. In addition, PCM can be divided into organic, molten salt, alloy, and composite according to material composition, and each of them has obvious advantages and disadvantages (Table 1). Among them, paraffinic materials are a typical solid-liquid organic PCM, and its working principle is as follows: when the ambient temperature is higher than the phase change temperature, the heat absorbed by the material changes from solid to liquid state; When the ambient temperature is lower than the phase transition temperature, the material releases heat from a liquid state to a solid state, thereby maintaining the ambient temperature at a suitable level (Figure 1).

temperature at a suitable level (Figure 1)

Table 1: Classification of phase change materials and their comparative analysis of their advantages and disadvantages

Source: Energy Storage Science and Technology

Fig.1 Basic process of solid-liquid phase change (material source network)

This kind of material has become an ideal energy storage material because of its high latent calorific value and energy storage density per unit mass, wide range of phase change temperature, convenient application, high stability, non-toxic, weak corrosiveness, low subcooling degree and reusability. At the same time, they are widely used in solar energy conversion and storage, electronic thermal management, building energy efficiency, waste heat utilization and peak electric heat storage systems. However, conventional phase change materials have two obvious disadvantages: (1) the thermal conductivity of the material is low (only 0.2W/(m· k) about), which greatly slows down the rate at which it absorbs and releases heat; (2) Paraffin wax is prone to leakage during use, and the volume of paraffin wax will increase by one-tenth after melting, which will cause the contraction and rupture of the matrix, resulting in the unusability of the product or even more unknown hazards.

As a national high-tech enterprise specializing in the application and development of low-dimensional nanomaterials such as graphene, Morion Nanotech has carried out industrialization layout in four directions: thermal management, new energy, functional composite materials, and biological health around the graphene R&D matrix. In response to the above problems, the R&D team of Morion Nanotech pioneered the three-dimensional structuring of graphene to obtain a graphene diaphragm with a unique micro-nano cavity structure, and used traditional phase change materials such as paraffin wax to fill it, and developed a new composite phase change material - graphene micro-nano cavity phase change vapor chamber. The product ushered in the industry premiere on February 25, 2022, and the market response was strong.

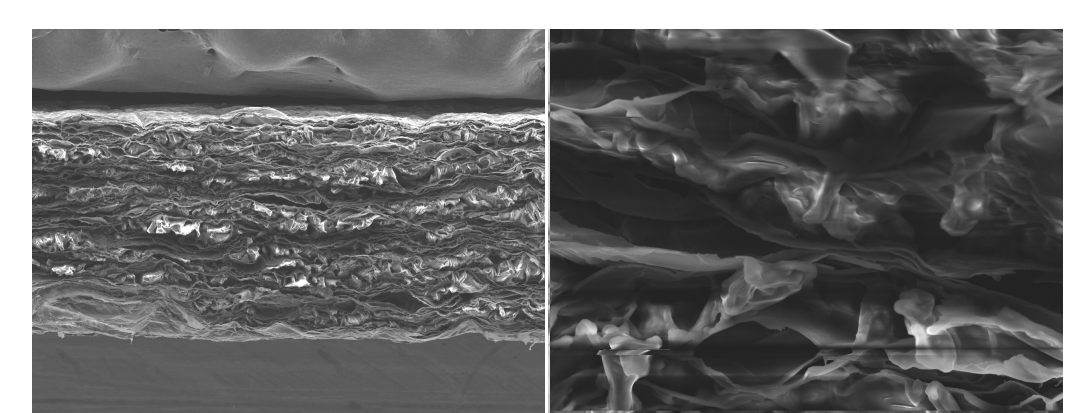

Due to the unique micro-nano cavity in its structure, the high strength of graphene (tensile strength of 130 GPa) and its good toughness, the phase change filler is well "locked" in the skeleton, which can greatly avoid the loss of filler and the destruction of the skeleton even when multiple phase transitions occur, and ultimately ensure the stability of the product performance (Fig. 2). At the same time, graphene is the material with the highest known thermal conductivity (>5300 W/mK), in addition to providing a stable support framework for the phase change filler, its high thermal conductivity helps the heat source heat to be transferred quickly and evenly into the micro-nano cavity structure of the product, so that the phase change filler in the structure undergoes phase change and efficient heat storage, and the overall thermal response rate of the product is very fast, and finally realizes the rapid cooling effect, thereby reducing the excessive waste or loss of energy in electronic products and other application scenarios.

Fig.2 SEM diagram of Morion Nanotech @ graphene micro-nano cavity phase change vapor chamber

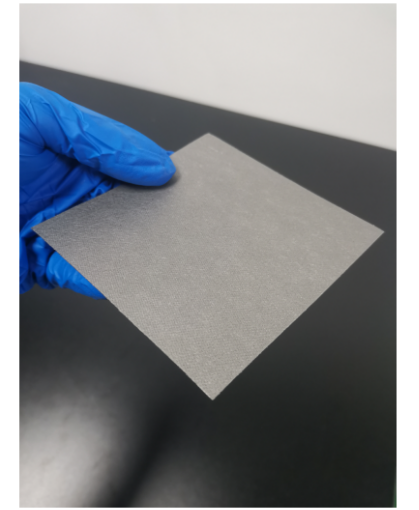

Up to now, Morion Nanotech has achieved large-scale mass production of a variety of products with different thicknesses and phase change temperatures, and the production process is stable, and customers can customize it according to their own requirements. The product fundamentally solves the problems of insufficient thermal conductivity, leakage and matrix shrinkage and rupture of phase change materials, and at the same time, the product performance is excellent and practical. Taking TCM-037 as an example, its enthalpy value is more than 200J/g, the in-plane thermal conductivity is more than 40W/(m·K), and the product has passed REACH, RoHS, halogen-free and other environmental testing certifications (Fig. 3, Fig. 4). Under the background of the country's vigorous promotion of the realization of the "double carbon" goal, the R&D team of Morion Nanotech will continue to work hard to develop more and better energy-saving and environmentally friendly materials while continuously optimizing existing products and improving performance, so as to help achieve the "double carbon" goal as soon as possible.

Fig.3 Morion Nanotech @ graphene micro-nanocavity phase change vapor chamber product information

Fig.4 Morion Nanotech @ Graphene Micro-Nano Cavity Phase Change Vapor Chamber, SGS Environmental Protection Testing and Certification

*The copyright of the content belongs to Morion Nanotechnology Co., Ltd. The pictures and articles shall not be reproduced without permission, nor shall the published content be distorted or tampered with. If reproduced, the source of the pictures and text shall be noted: Morion Nanotechnology Co., Ltd.

Guangdong Public Security Registration No.44190002005690

Guangdong Public Security Registration No.44190002005690